Date:Sep 13, 2022

National & Local Joint Engineering Research Center of E-government Simulation (Liaoning)

Introduction

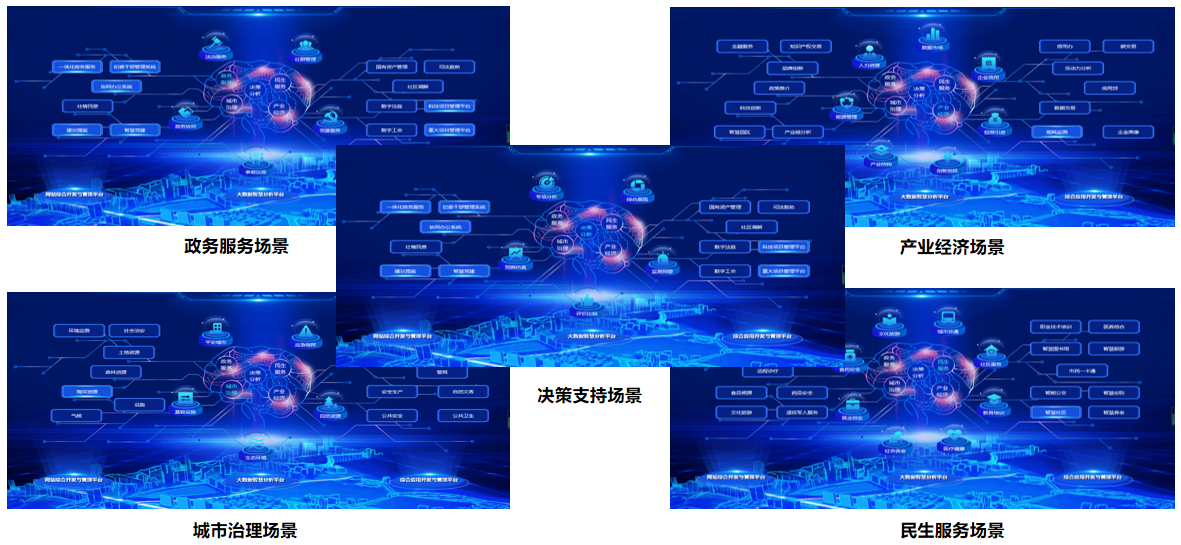

The National & Local Joint Engineering Research Center of E-government Simulation (Liaoning) was approved for construction by the National Development and Reform Commission in November 2011. The Center is subordinate to the DUT School of Economics and Management, which boasts the national key discipline and first-level discipline of Management Science and Engineering. Focusing on digital government and intelligent social governance, the Center mainly devotes efforts to theoretical research and development of key technologies and service platforms driven by the combination of data and knowledge. Its research directions include research and development of theoretical approach and key common technologies and business platforms on digital government, intelligent emergency response and management, intelligent social governance and their business platform development, formulation of industry codes and standards, as well as consultancy services on digital government and social governance. Its research results have served over 300 Party and government bodies involving state organs, ministries and commissions, provinces, municipalities, and counties/districts.

Contact: Su Xiaoyan E-mail: sxy@dlut.edu.cn

Update: The name of the director is changed from Wang Yanzhang to Ye Xin in the Excel sheet.

Figures: Research output of the Center

National & Local Joint Engineering Laboratory of Energy Saving Control Technology for Industrial Equipment

Introduction

The National & Joint Engineering Laboratory of Energy Saving Control Technology for Industrial Equipment is grounded in the first-class discipline – Control Science and Engineering of the Dalian University of Technology (DUT). The Laboratory has 10 professors and 23 associate professors with a varied academic background including control theory, control engineering, computer software, network technology, embedded technology, and other disciplines. Especially in terms of the field-bus control system and advanced control theory and engineering application, it possesses distinct advantages through interdisciplinary and complementary backgrounds.

Now, a high-level scientific research team focusing on basic theoretical and application research has taken shape with a clear research direction and a reasonable knowledge structure. To address major needs of the state and the industry, the Laboratory has carried out a wide range of researches on field-bus energy-saving control theory and methods based on the industrial ethernet, the optimization control technology of intelligent testing and energy saving for major industrial equipment, energy-efficient control technology of equipment and system, enterprise energy monitoring and management technology, energy-efficient and efficiency-raising technology based on optimal dispatching of the production process. Therefore, the Laboratory has developed a set of leading energy-saving control theories as well as technology and engineering application system for industrial equipment.

Over the recent years, the Laboratory has undertaken more than 50 research projects and licensed 30 invention patents. Over 150 doctoral and postgraduate students have graduated and more than 100 academic papers have been published. In the future, the Laboratory will forge ahead with innovation and creativity with a focus on Energy Saving Control Technology for Industrial Equipment. It will help enterprises enhance their capacity for energy management and control and enable enterprises to achieve carbon peaking and neutrality goals.

Contact: Lu Wei E-mail: luwei@dlut.edu.cn

National & Local Joint Engineering Research Center of Advanced Equipment Design and CAE Software Development

Introduction

The National & Local Joint Engineering Research Center of Advanced Equipment Design and CAE Software Development was approved by the National Development and Reform Commission in 2013. Computational analysis, analog simulation, and design and control optimization technologies in the design and manufacturing of advanced equipment and industrial products (i.e. Advanced CAE) are the core technologies of technological innovation and digital and intelligent design and manufacturing, taking the strategic high point for transforming traditional industries and developing cutting-edge technologies for national defense. The advanced CAE is important and extensively demanded in the manufacturing industry and the national economy. The Center mainly focuses on forward-looking and key research and development (R&D) involving structural analysis, optimal design and CAE software in advanced equipment R&D. Research fields mainly include key generic technologies of advanced design and CAE, R&D for platform and product of CAE software, promotion and application of advanced equipment design technology, etc.

Relying on the Department of Engineering Mechanics of Dalian University of Technology and the State Key Laboratory of Structural Analysis for Industrial Equipment, the Center boasts a first-level national key discipline of Mechanics and a high-level research team.

Contact: Kang Zhan Tel: 13190104312; Chen Biaosong Tel: 13898628122

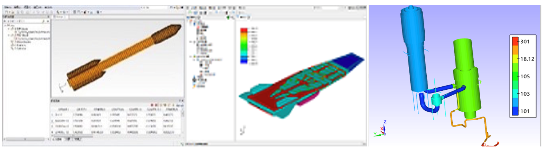

Fig. 1 SiPESC (independently-developed new generation of software platform for computational mechanics), being able to realize finite element analysis, design optimization and visualization of structures with tens of millions/hundreds of millions of degrees of freedom

Fig. 2 Typical engineering applications of SiPESC: structural dynamics model updating; overall optimization on design of aircraft structures; structural analysis of nuclear power pipelines

National & Local Joint Engineering Laboratory of Bridge and Tunnel Technology

Introduction

The National & Local Joint Engineering Laboratory of Bridge and Tunnel Technology consists of the laboratory of bridge and tunnel structures and the laboratory of wind tunnel. With an area of about 5000 square meters, the laboratory of bridge and tunnel structures is equipped with large shear compression machines, fatigue testing machines, shaking tables, pools, geotechnical boxes, actuators, universal testing machines and other devices, which can meet the need for research on large-scale structural models, components and materials for dynamic and static testing.

With an area of about 1000 square meters, the laboratory of wind tunnel has a 18m-long, 3m-wide and 2.5m-high section for experiments with fully automatic measurement and control system, which can be used for wind resistance test on bridge and building structures. The Laboratory has competent capabilities with more than 80 scientific researchers, forming an industry-university-research combined team integrating teaching, scientific research, design, construction monitoring, health monitoring, testing and evaluation, and maintenance and reinforcement.

The Laboratory has completed more than 100 scientific research projects such as the National Natural Science Foundation of China Projects, the National Key Technologies R&D Program and the Provincial Key Fund Projects, and more than 300 engineering service projects in major engineering design, construction monitoring, inspection, health monitoring, etc., including the Dalian Xinghai Bay Cross-sea Bridge project.

Contact: Qiu Wenliang Tel: 13842877202 E-mail: qwl@dlut.edu.cn

Fig. 1 Laboratory of bridge and tunnel structures

Fig. 2 Laboratory of wind tunnel

National & Local Joint Engineering Laboratory of Manufacturing Management Information Technology

Introduction

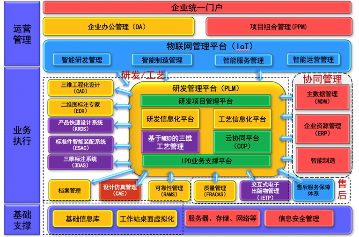

Based on Dalian University of Technology and cooperating with Dalian Hi-think Computer Technology Co., Ltd (Dalian Huaxin), the National & Local Joint Engineering Laboratory of Manufacturing Management Information Technology is a national-level innovative platform for scientific research established with the approval of the National Development and Reform Commission in 2015. Focusing on complex equipment manufacturing, particularly management of manufacturing system, its research team adopts the integrated model of industry-university-research-application and undertakes nearly 200 projects at various levels including the National High-tech R&D Program of China (863 Program), National Science and Technology Infrastructure Program, National Key R&D Program of China, National Science and Technology Major Project of China, provincial and municipal key technologies R&D programs, and technological updating of enterprises.

Its research will mainly focus on intelligent manufacturing, management of manufacturing technologies and manufacturing management and will carry out research on key technologies of intelligent manufacturing management and industrial generic technologies that restrict the growth of enterprises in the future, with the aim to provide the industry with experiment and testing environment for technology development and engineering, and to develop management solutions for intelligent manufacturing and information products with Chinese characteristics as well as pertinence to the industry. Currently, its research results have been widely applied by hundreds of enterprises engaging in rail traffic, aerospace, automobile manufacturing, ship building and repairing, ferrous metallurgy, heavy equipment, financial equipment, etc., some of which have achieved world-class standards and taken the lead in China.

Contact: Bai Chaoyang E-mail: baizhaoyang@dlut.edu.cn

Update: The name of director is changed to Zhu Fangwei in the Excel sheet.

National & Local Joint Engineering Research Center of Comprehensive Utilization Technology of Thermal Energy

Introduction

The National & Local Joint Engineering Research Center of Comprehensive Utilization Technology of Thermal Energy (the Center) was approved by the National Development and Reform Commission in 2017 (No. 2216 [2017] of the Department of Innovation and High-Tech Development of the National Development and Reform Commission). The Center, subordinate to DUT School of Energy and Power Engineering, is based on the discipline of Power Engineering and Engineering Thermophysics. It currently has 75 researchers, including 25 professors and 45 associate professors, 60 of whom have a doctoral degree.

In accordance with important and latest issues at home and abroad and the National Medium- and Long-Term Development Plan, the Center takes thermal energy comprehensive utilization technology as the focus of its work to summarize rules of industrial operation and management. It carries out studies on research and development of new technologies and engineering application in such fields as seawater desalination in hydro power generation, efficient utilization of low-grade thermo energy, high salinity wastewater treatment, new energy, combined cycle power, waste heat recovery, and energy management, and its achievements in theoretical studies and application of engineering technologies of seawater desalination have attracted great attention from peers at home and abroad. It has developed much advanced equipment including devices for large seawater desalination and for efficient heat transfer, and established platforms for new technologies for energy conservation and environment protection as well as transformation of related research results, so as to help achieve carbon peak and carbon neutrality.